In modern industrial and consumer applications, the demand for materials that combine flexibility, ease of use, and long-term durability has significantly increased. Among these, PVC self-adhesive materials have emerged as a versatile solution across sectors such as construction, packaging, automotive, and interior design.

PVC, or polyvinyl chloride, is a synthetic plastic polymer known for its stability, chemical resistance, and versatility. When formulated as self-adhesive film materials, PVC combines these intrinsic properties with a pressure-sensitive adhesive layer, allowing it to attach securely to a wide range of surfaces without the need for additional bonding agents.

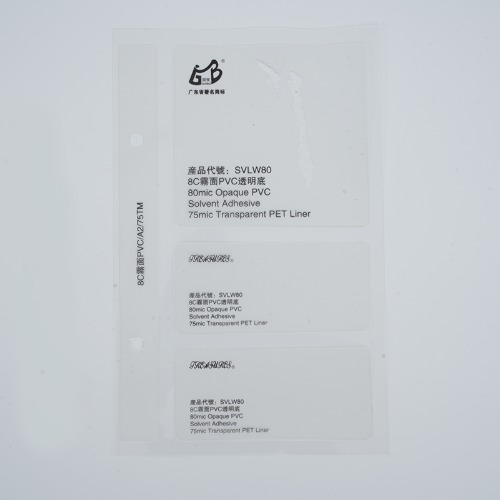

The composition of PVC self-adhesive materials typically includes three essential components:

| Component | Function |

|---|---|

| PVC Film Layer | Provides structural integrity, flexibility, and resistance to environmental factors such as moisture and UV exposure |

| Adhesive Layer | Ensures strong bonding to surfaces, maintaining adhesion over extended periods under varying temperatures and pressures |

| Release Liner | Protects the adhesive before application, facilitating easy handling and precise installation |

The synergy between these layers is critical for ensuring both durability and reliability, making PVC self-adhesive materials suitable for long-term applications.

Several characteristics of PVC self-adhesive materials contribute directly to their longevity:

PVC materials inherently offer high tensile strength and resistance to tearing. This ensures that self-adhesive films maintain their shape and do not easily deform under mechanical stress, even in high-traffic or high-impact environments.

PVC films exhibit resistance to environmental factors such as moisture, heat, and UV radiation. Matte PVC surfaces, in particular, reduce glare while maintaining stability, preventing premature degradation in outdoor or high-exposure settings.

Many self-adhesive film materials resist chemicals, oils, and stains, making them suitable for industrial applications where exposure to harsh substances is common. The PVC layer acts as a protective barrier, preserving both appearance and functionality.

The quality of the adhesive layer is crucial for long-term performance. Modern PVC self-adhesive materials are formulated to maintain adhesion over years without peeling or shrinking, even when applied to challenging surfaces such as textured walls, metal, or plastic composites.

Matte PVC, characterized by its non-reflective surface, not only provides aesthetic appeal but also enhances functional durability. Its surface structure reduces visible scratches, fingerprints, and smudges, contributing to a clean, long-lasting finish. Additionally, matte PVC films are less prone to UV-induced yellowing, ensuring consistent appearance over time.

| Feature | Matte PVC Benefit |

|---|---|

| Non-reflective surface | Reduces glare and visible scratches |

| UV resistance | Prevents discoloration and maintains surface integrity |

| Fingerprint resistance | Keeps surfaces clean in high-touch areas |

| Enhanced adhesion | Works effectively with pressure-sensitive adhesives |

The versatility of PVC self-adhesive materials makes them indispensable in various applications:

PVC adhesive sheets are widely used for wall coverings, furniture protection, and decorative panels. Their durability ensures that they withstand cleaning, abrasion, and minor impacts without losing adhesion or aesthetic quality.

In industrial settings, durable PVC films serve as protective coatings for machinery, surfaces, and packaging. Their chemical and moisture resistance safeguards underlying materials from corrosion, dirt, and mechanical wear.

Self-adhesive PVC films are applied in automotive interiors and exteriors, such as dashboard covers, trim, and protective films for painted surfaces. The material’s flexibility allows it to conform to curved surfaces while maintaining strong adhesion.

PVC self-adhesive materials are a preferred choice for long-term signage due to their environmental stability and ease of application. Matte PVC films reduce reflection, ensuring high readability under various lighting conditions.

To ensure both durability and reliability, several quality factors must be considered when selecting PVC self-adhesive materials:

| Factor | Description |

|---|---|

| Film Thickness | Thicker films generally provide higher mechanical strength and longer lifespan |

| Adhesive Type | Acrylic or rubber-based adhesives influence bonding strength and resistance to environmental factors |

| Surface Texture | Smooth or matte finishes affect scratch resistance, visual appeal, and adhesion performance |

| Environmental Testing | Materials tested for UV, moisture, and temperature stability offer better long-term reliability |

Even high-quality PVC self-adhesive materials require proper installation to achieve durability:

Following these practices extends the functional lifespan of self-adhesive film materials, reinforcing their reputation for reliability.

Recent advancements in PVC technology have introduced enhanced flexibility, scratch resistance, and eco-friendly formulations. High-performance adhesives paired with durable matte PVC films allow these materials to perform reliably even in environments, opening opportunities for broader industrial applications.

| Feature | Traditional PVC | Advanced PVC Self-Adhesive Film |

|---|---|---|

| Tensile Strength | Moderate | High |

| UV Resistance | Basic | Enhanced |

| Adhesion Durability | 3–5 years | 7–10 years |

| Surface Finish | Glossy or standard | Matte, fingerprint-resistant, anti-scratch |

The table illustrates how modern innovations improve durability, reliability, and overall performance, making advanced PVC films a preferred solution across sectors.

Durable PVC materials also meet various environmental and safety standards. Low-VOC adhesives and non-toxic formulations reduce harmful emissions during installation and usage. Additionally, the long lifespan of these films minimizes replacement frequency, contributing to reduced material waste.

PVC self-adhesive materials offer a unique combination of durability, flexibility, and reliability. Through careful material selection, advanced adhesive technology, and proper installation, these films perform consistently across diverse applications, from interior decoration to industrial protection. Matte PVC variants further enhance longevity, maintaining both aesthetic and functional integrity over time.

Q1: What surfaces are compatible with PVC self-adhesive materials?

PVC self-adhesive films can adhere to various surfaces including glass, metal, wood, plastic, and painted walls. Surface preparation improves adhesion and longevity.

Q2: How long can PVC self-adhesive films last?

With proper installation and maintenance, high-quality PVC self-adhesive films can last 7–10 years, depending on environmental exposure and usage conditions.

Q3: Is matte PVC suitable for outdoor applications?

Yes, matte PVC films resist UV damage and discoloration, making them suitable for outdoor signage, decorative panels, and protective coatings.

Q4: Can PVC self-adhesive materials be repositioned after application?

Certain flexible self-adhesive materials allow temporary repositioning during installation, but permanent adhesion typically develops within 24–48 hours.

Q5: Are PVC self-adhesive materials environmentally safe?

Modern PVC films use low-VOC adhesives and non-toxic formulations, reducing environmental impact while ensuring safe handling and use.